About company

CJSC "Kubancabel" ("ZAO Kubankabel")

Dynamically developing enterprise with 25 years of experience, at which assembly, fiber optic, telephone, control, power cables manufacturing is arranged.

Dynamically developing enterprise with 25 years of experience, at which assembly, fiber optic, telephone, control, power cables manufacturing is arranged.

"ZAO Kubankabel" ideology is the high quality products manufacturing. We consider as unacceptable the methods to reduce the production cost, leading to its quality deterioration, which is ensured by the following factors:

- production processes are based on the application of high quality materials and advanced technologies with entire process streams compliance;

- automated systems of production lines allow for the in-process production parameters control and ensure the quality parameters stability along the entire length of the product;

- entire cable manufacturing process sustainability is ensured by a carefully selected personnel, those professional level is constantly increasing.

Our advantages:

- optimal lead-time;

- manufacturing of products for the special requirements to the length multiplicity;

- support of each cable lot, sent to the customer, with conformity certificates and protocols of acceptance;

- protection against a purchase of low-quality and counterfeit cable: laser cable marking, holographic label on the label and the test report; the QR-code, which has got product basic information encrypted;

- continuous search for new designs and materials to develop new products and improve manufacturability;

- product terms of shipping – either ex works, or rail and road transport.

New types of products:

- For new products manufacturing the high fire safety requirements materials are used, such as low flammability /low smoke and gas emission PVC composition, with low toxicity of combustion products ("ng-LSLTx"), and halogen-free polymeric compositions, with low toxicity of combustion products ("ng-HFLTx").

- Telephone cables TU 3572-040-76960731-2016 range is expanded. The distinctive design feature of these cables is the "dry performance" - hydrophobic filling is replaced by water swelling tape to prevent longitudinal propagation of moisture in the event of the outer shell damage. A variety of insulation and jacketing materials (polyethylene, PVC plasticized of fire safety degrees, cross-linked polyolefin, thermoplastic elastomers) allows to expand the temperature range of operation and installation.

- There were developed and implemented in the production the Universal Optical Cables GERD-SAC-III with optical fiber in tight buffer coating (tight buffer) of 900 microns. Small diameter, light weight, increased flexibility of the cable facilitate installation in the completed tracks. The absence of the hydrophobic filling allows to lay cables both horizontally and vertically.

- The cables with additional rodent protection there were launched.

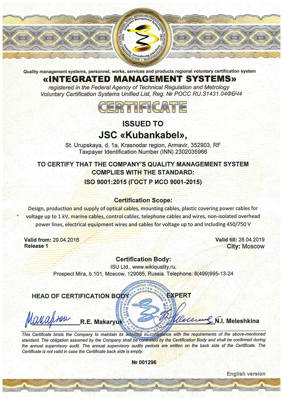

The company has developed and implemented a Quality Management System (QMS) that meets the requirements of ГОСТ Р ISO 9001-2015 (ISO 9001: 2015), ГОСТ РВ 0015-002-2012.

The certificate of conformity to meet the requirements of GOST RV 0015-002-2012

The scope of certification - production and supply of cables according to EKPS (the codes of unified supplies codification).

- EKPS 5995 - Cables, cords, wire for radio and communications devices.

- EKPS 6145 - Electrical wires and cables.

- EKPS 6015 - Fiber-optic cables.